Introduction: The Art and Challenge of Large Pillar Candles

Large pillar candles hold a timeless place in luxury spaces — from grand hotel lobbies and wedding receptions to serene home interiors and festive gatherings. Their commanding presence brings both warmth and sophistication. However, as their size increases, so do the technical challenges behind creating a candle that burns evenly, smells delightful, and maintains structural integrity over hours of use.

At Circe Home, we believe that “size should never compromise performance.” In this guide, we explore the craftsmanship and science of ensuring quality with large pillar candles, focusing on burn consistency, scent stability, and design excellence. Whether you are a brand owner, wholesaler, or designer seeking reliable OEM solutions, understanding these fundamentals helps ensure every candle glows beautifully — and safely.

Understanding Burn Quality Metrics

Quality in pillar candles isn’t just about appearance; it’s about performance. A well-crafted large candle should burn evenly, produce minimal soot, and release fragrance steadily. Three core metrics define burn quality:

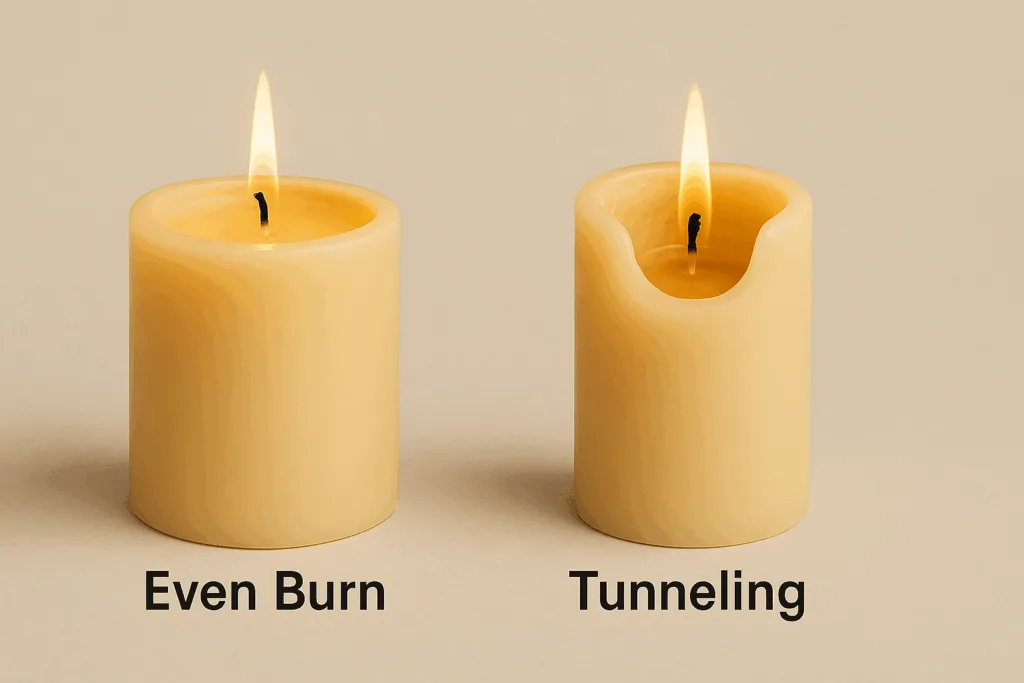

1. Even Burn

A balanced flame ensures that wax melts uniformly, avoiding tunneling (when wax burns down the middle, leaving hard walls). To achieve this:

- Blend waxes like soy and beeswax for optimal melting points.

- Use centered cotton or wooden wicks of precise diameters.

- Design molds with proportional wall thickness to guide heat distribution.

Even burn not only improves longevity but also creates a consistent aesthetic as the candle melts.

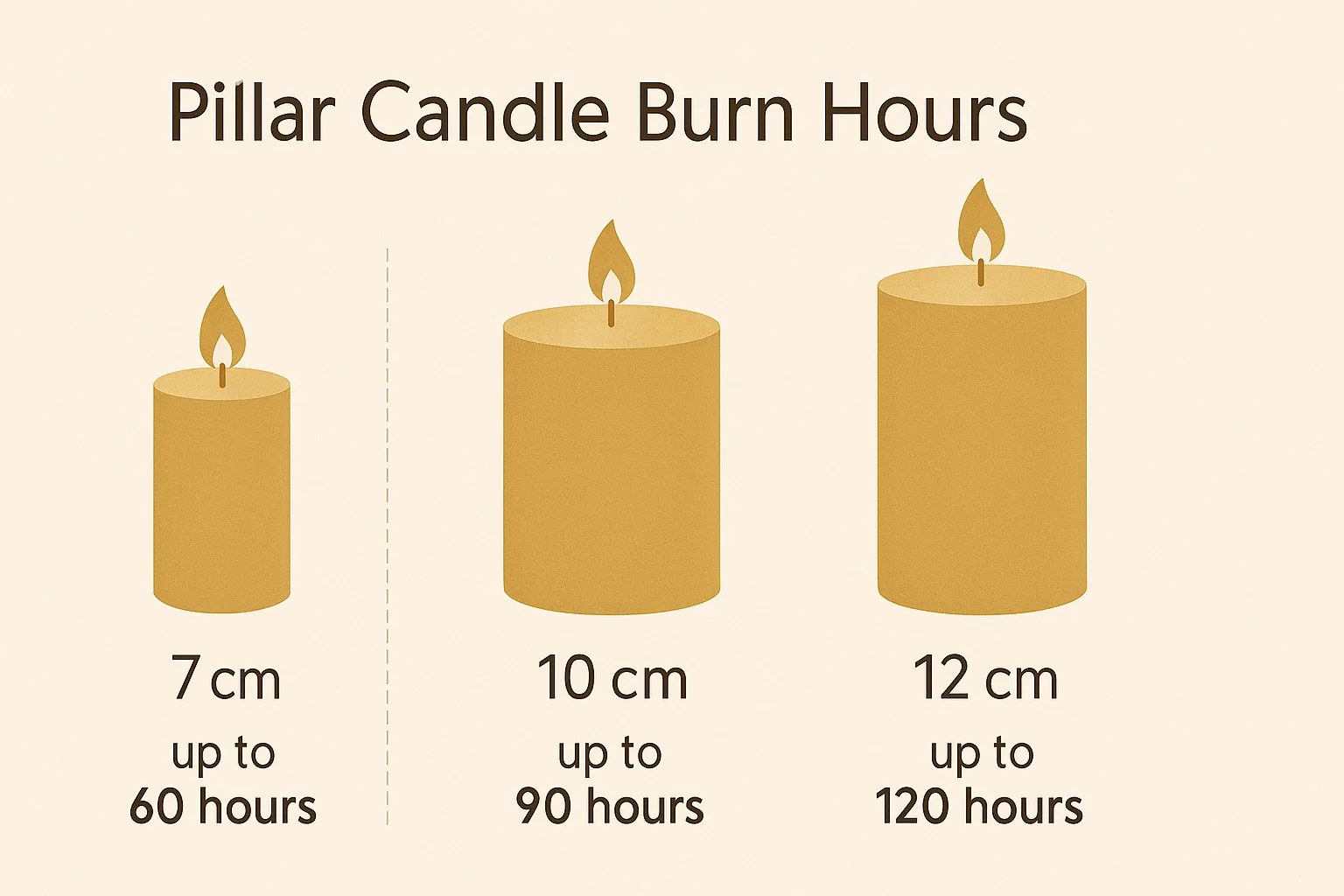

2. Burn Time Consistency

The ideal burn time depends on diameter and wax density. For example:

| Diameter | Ideal Burn Time | Wax Type |

| 7cm | 40–45 hours | Soy blend |

| 10cm | 70–80 hours | Beeswax blend |

| 12cm | 100+ hours | Paraffin-free mix |

Manufacturers like Circe Home perform first-burn tests to validate duration and adjust wick size or wax ratios accordingly.

3. Scent Throw & Stability

Large candles require powerful yet stable scent diffusion. This involves:

- Testing both cold throw (unlit aroma) and hot throw (burning fragrance).

- Using microencapsulated fragrance oils to enhance scent longevity and prevent degradation.

A well-formulated pillar candle maintains its scent strength even after multiple burns.

Design & Structural Integrity

Design affects not only aesthetics but also burn quality and safety. Circe Home engineers each candle around the golden proportion (height-to-width ≈ 2:1), balancing stability and beauty.

Proportion & Aesthetics

Surface finishes — smooth, textured, layered — influence how light interacts with the wax. For example:

- Smooth finishes amplify reflections and suit modern spaces.

- Textured patterns hide burn imperfections and add depth.

Proportion also ensures airflow around the wick remains consistent, aiding even combustion.

Mold & Pouring Techniques

Crafting large pillar candles requires precise layering and temperature control. Improper cooling can cause sinkholes or internal cracks. Circe Home uses:

- Multi-stage pouring to reduce air pockets.

- Slow cooling protocols to preserve symmetry and surface smoothness.

Heat Resistance & Crack Testing

Each candle undergoes heat endurance tests, simulating long burns in various temperatures. Results confirm structural reliability — no softening, dripping, or cracking. Only candles passing all tests reach the market.

Material & Sustainability Standards

Today’s buyers demand eco-conscious products without compromising beauty or performance. Circe Home integrates sustainability in every step:

| Material | Key Benefit | Eco Feature |

| Soy Wax | Clean burn | Renewable & biodegradable |

| Beeswax | Natural gloss | Non-toxic, supports beekeeping |

| Coconut Wax | Excellent scent throw | Sustainable crop source |

Wicks are lead-free cotton or crackling wood, while packaging uses recyclable paper and water-based inks. All products comply with EN15493 (burn safety) and EN15494 (labeling) standards, along with REACH and RoHS certifications.

Quality Assurance Process

Circe Home’s multi-tier quality assurance ensures every candle meets international OEM expectations:

- Raw Material Testing:

- Wax purity and fragrance ratio checks.

- Visual inspection for color consistency.

- Pre-Burn & Stability Tests:

- Wick performance and flame height evaluation.

- Tracking soot output and melt pool diameter.

- Customer Validation:

- Pre-shipment photo approval and sample verification.

- Optional third-party lab certification.

This process guarantees dependable, repeatable quality for every production batch.

OEM & Brand Differentiation

Circe Home empowers global brands through flexible customization and reliable logistics:

- Customization Options: Size, color, embossed logos, fragrance intensity, and packaging.

- MOQ Flexibility: Small-batch sampling or bulk OEM runs.

- Global Support: Warehousing and express delivery worldwide.

The Circe Home OEM advantage lies in design consultation and standardized burn performance, ensuring your brand always shines — literally and figuratively.

Design Personalization and Packaging Innovation

From minimalist modern looks to festive designs, presentation defines perception. Circe Home offers:

- Embossed brand logos for exclusivity.

- Personalized labels and gift-ready boxes.

- Sustainable packaging using FSC-certified materials.

Good packaging tells a story — and Circe Home helps brands craft that narrative visually and ethically.

Circe Home Advantage: Where Art Meets Precision

Each Circe Home candle embodies both artistry and engineering precision. Our manufacturing integrates automated pouring with human craftsmanship — ensuring no detail is overlooked. Clients value:

- Consistent burn performance across batches.

- Design consultation from concept to prototype.

- Environmentally responsible sourcing.

This combination makes Circe Home a trusted OEM partner for hotels, retailers, and luxury brands globally. Learn more about sustainable candle standards here.

Conclusion: Quality Defines the Glow

Creating a perfect large pillar candle is a balance of science, design, and dedication. From wax blending to mold design, from scent balance to heat testing, every step defines the final glow.

At Circe Home, we believe:

“Size means prestige—but only quality sustains trust.”

Partner with a manufacturer who understands the art and science of burn perfection.

FAQ: Ensuring Quality with Large Pillar Candles

1. What causes tunneling in large pillar candles?

Tunneling occurs when the wick is too small or off-center, causing uneven melting. Proper wick sizing and wax blend balance prevent this issue.

2. How long should a 10cm pillar candle burn?

Typically, between 70–80 hours, depending on wax density and wick type. Always perform first-burn tests to validate consistency.

3. Are natural waxes better for large candles?

Yes. Soy and beeswax blends offer cleaner burns, less soot, and longer burn times while being eco-friendly.

4. How can brands customize pillar candles with Circe Home?

Options include color, fragrance, embossing, logo imprinting, and packaging. OEM clients can also request private labeling.

5. What certifications ensure candle safety?

Look for EN15493, EN15494, and REACH standards. Circe Home complies with all relevant regulations.

6. Why do large candles sometimes crack after cooling?

Rapid temperature change during solidification creates internal stress. Controlled cooling and layered pouring eliminate this issue.