The Rising Demand for Custom Ceramic Candle Jars in the Global Market

Ceramic candle jars have become one of the most desired packaging solutions among premium fragrance brands around the world. As consumer lifestyles shift toward wellness, interior aesthetics, and personal rituals, the demand for elegant, durable, and emotionally appealing candle vessels continues to rise. For B2B buyers, ceramic jars offer a unique blend of artistry and performance, creating a luxurious impression that elevates any candle line.

One major driver behind this demand is the growing focus on ambience at home. Post-pandemic habits have led people to spend more time indoors, curating warm and calming environments with natural textures, soft light, and rich fragrances. Ceramics align perfectly with this lifestyle, providing a handcrafted feeling no other material can replace.

Additionally, global consumers now favor products that blend beauty with longevity. Ceramic containers check all the boxes: they are reusable, heat-stable, elegant, and compatible with a wide range of wax types and scent intensities. This makes them a smart investment for brands aiming to position themselves in the mid-to-high-end market.

Ceramics also resonate especially well with wellness and spa brands. Their tactile surface, weight, and visual charm create a multi-sensory experience that strengthens the emotional value of the candle. Whether minimalist or richly glazed, each ceramic jar has a story—and modern consumers appreciate products that feel meaningful and authentic.

Industry Trends Shaping Modern Ceramic Candle Packaging

The candle industry is undergoing rapid transformation driven by lifestyle shifts, consumer consciousness, and global aesthetic trends. Ceramic jars sit at the intersection of these trends, benefiting from their timeless appeal.

Nature-Inspired Minimalism

There is a rising preference for organic shapes, soft matte finishes, and nature-inspired textures. Ceramic materials naturally lend themselves to these styles. Reactive glazes, unglazed stoneware, and clay-like finishes reflect the desire for grounded, earthy design.

Clean Fragrance Movement

As more consumers lean toward phthalate-free, plant-based, and non-toxic scent systems, brands are choosing packaging that reinforces their clean identity. Ceramic—being a stable, heat-resistant, and inert material—supports the narrative of purity.

Hybrid Lifestyle

The blend of working from home, intentional self-care routines, and micro-luxuries leads to candles being used daily. This encourages brands to choose durable and reusable jars, positioning ceramics as the premium choice.

Sustainability and Transparency in Ceramic Candle Jar Production

Sustainability is becoming a non-negotiable factor in product design. Ceramic vessels stand out due to their long lifespan and eco-friendly potential.

Eco-Friendly Glazes and Lead-Free Standards

High-quality ceramics use lead-free, cadmium-free glazes. As brands expand into the EU and U.S. markets, certifications such as LFGB, REACH, and CA65 become essential.

Transparent Sourcing

Buyers now expect transparency regarding clay origins, glaze composition, and firing processes. Ethical sourcing is a selling point for modern candle brands.

Sustainable Packaging

Given the weight of ceramic jars, protective yet sustainable packaging options are key. Many brands now opt for biodegradable inserts, recycled kraft boxes, and water-based printing.

Innovation and Scent-Tech in Modern Candle Manufacturing

Technology is transforming how brands design candles, especially when paired with ceramic jars.

AI-Assisted Scent Design

AI tools help create layered, complex scent profiles based on geographical preferences, seasonal demands, and emotional mapping.

Thermal Engineering

Ceramics maintain heat longer than glass, supporting a more stable burn curve and richer scent throw. Engineers now optimize jar thickness and shape to enhance fragrance diffusion.

Multi-Sensory Candle Concepts

Ceramic’s versatility enables combinations of texture, color, weight, and pattern—turning candles into multi-sensory art pieces.

MATERIAL SCIENCE & CONTAINER ANALYSIS — The Core of Ceramic Candle Quality

Material science affects every aspect of candle performance.

Density, Porosity, and Heat Resistance

High-density ceramics reduce sweating, cracking, and uneven burn. Proper firing temperatures (1200–1300°C) create durable, non-porous walls.

Glaze Chemistry

Glaze influences scent perception, durability, and colorfastness. Premium glazes resist staining, withstand heat, and maintain vibrant color over time.

Material Origins

Different regions produce vastly different ceramic qualities:

- Jingdezhen: fine porcelain, ultra-smooth surfaces

- Dehua: warm-toned white clay, ideal for luxury goods

- Northern China Kilns: earthy stoneware with organic textures

Market Positioning

Material provenance enhances brand storytelling—key to Western B2B customers seeking differentiation.

B2B Suitability

Engraving, decal application, relief patterns, and kiln-stable pigments allow ceramic jars to support high-end branding.

Ceramic vs. Glass vs. Metal Candle Jars

Each material has pros and cons.

Heat Conductivity

Ceramics retain heat longest, offering a more even burn.

Scent Throw

Ceramic’s heat stability means consistent scent diffusion throughout the burn.

Market Positioning

- Glass: mass market

- Metal: travel and tin candles

- Ceramic: boutique, luxury, design-forward brands

Global Scent Preferences and How Ceramic Influences Perception

Ceramics elevate fragrance in different ways depending on the region.

North America

Prefers clean, cozy, and comforting scents—ceramic jars reflect this aesthetic.

Europe

Values craftsmanship, sustainability, and heritage design.

Oceania

Emphasizes natural, botanical, and coastal themes that pair well with matte ceramics.

Design Considerations When Customizing Ceramic Candle Jars

Key factors influence the cost, appearance, and burn performance.

Shape and Volume

Thick-walled vessels support stable heating.

Glaze Options

Matte, glossy, crackle glaze, and reactive glazes each create unique visual effects.

Decorative Techniques

Embossing, engraving, decals, and relief patterns elevate brand identity.

Understanding the MOQ for Ceramic Candle Jars (1000+ Minimum)

One of the most important topics for B2B buyers: refined, beautifully crafted ceramic jars require a minimum order quantity of 1000 pieces.

This is not only industry standard—it is already a very friendly and low MOQ considering the craftsmanship and production steps involved.

Why 1000+ MOQ?

- High-temperature kilns require batch efficiency

- Mold creation and glaze matching are costly

- Firing loss (5–10%) must be accounted for

- Color consistency requires larger batches

How MOQ Affects Quality

Increasing order size improves color stability, reduces defects, and optimizes cost.

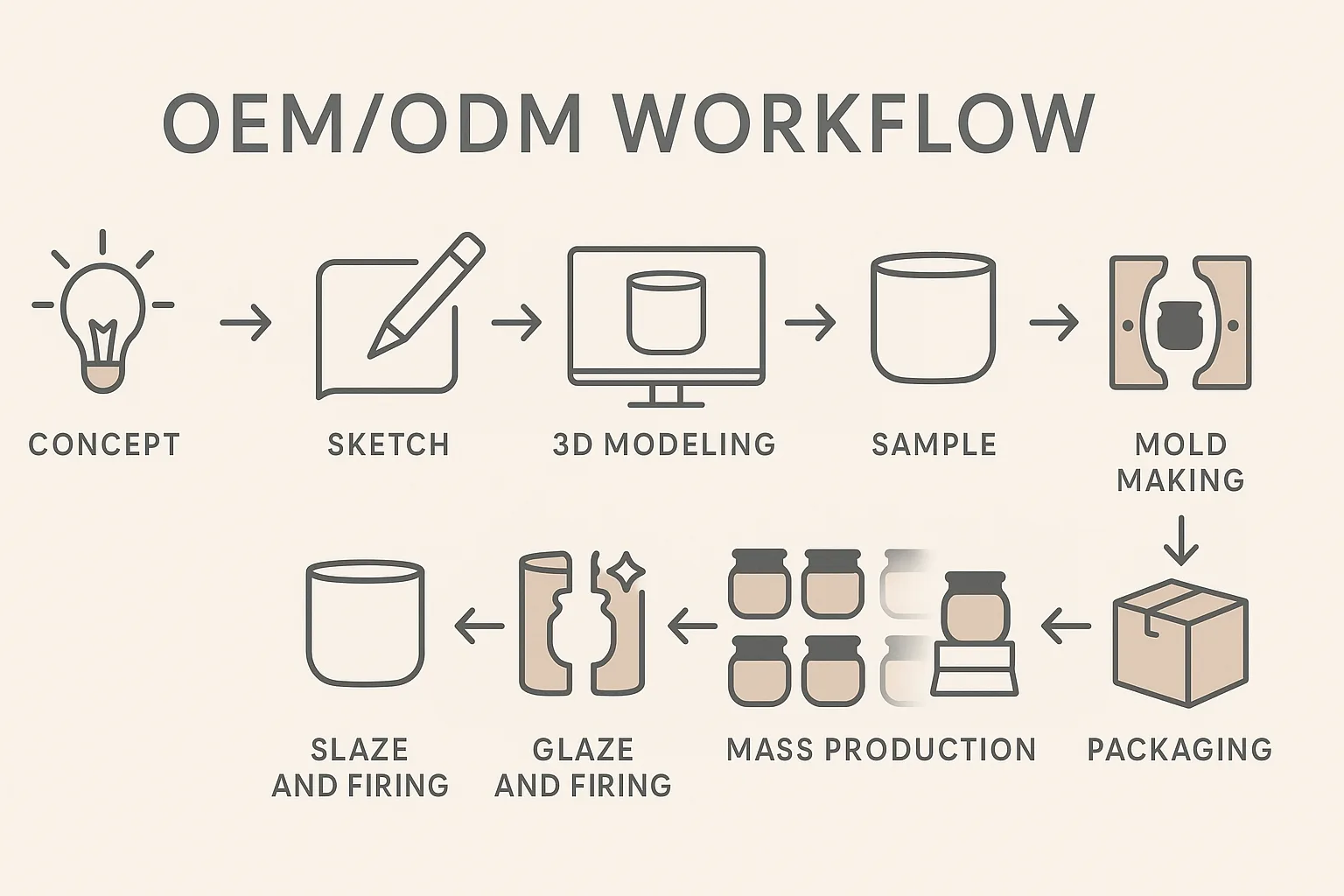

OEM/ODM Workflow for Custom Ceramic Candle Jars

The complete process from idea to finished product:

Step 1: Concept & Sketch

Step 2: 3D Modeling

Step 3: Sample Creation

Step 4: Mold Production

Step 5: Firing & Glazing

Step 6: Mass Production (1000+ MOQ)

Step 7: Quality Inspection

Step 8: Packaging & Logistics

Private Label Opportunities with Ceramic Candle Collections

Ceramic jars are ideal for:

- Seasonal collections

- Hotel and spa collaborations

- Boutique retail sets

Logistics & Global Shipping Considerations

Ceramic’s weight makes professional logistics essential.

FOB, EXW, DDP Options

Protective Packaging

Cost Optimization for Heavy Goods

Sustainability Advantages of Ceramic Containers

Ceramics last for years and can be reused as planters, storage containers, or décor pieces.

Pricing Structure for Custom Ceramic Candle Jars

Costs depend on:

- Clay type

- Glaze

- Size and thickness

- Decoration

- Mold fees

Higher quantities (3000+, 5000+) significantly reduce unit cost.

How Circe Home Ensures Premium Quality

Circe Home blends technical precision with artisanal design.

Expert Material Selection

Glaze Stability Testing

Tech + Craft Manufacturing Philosophy

Final Buying Checklist

- Material

- Glaze

- Thickness

- MOQ 1000+

- Packaging

- Certifications

Conclusion

Custom ceramic candle jars blend craftsmanship, durability, and refined aesthetics—making them one of the most powerful tools for brands aiming to elevate their candle collections. From material science to glaze selection, from MOQ requirements to global design trends, every detail shapes the final product’s performance and market value. For professional B2B buyers, understanding these factors ensures smoother production, stronger branding, and long-term consumer appeal.

As the demand for premium home fragrance continues to grow, ceramic jars offer not only beauty but strategic business advantages. With the right manufacturing partner and a clear understanding of design and technical considerations, your next ceramic candle collection can stand out globally and build lasting customer loyalty.